Wave Industries Pvt Ltd., one of the Major players of Sugar producing groups, has it’s Sugar Complex at Dhanaura, UP (W) and expanded its footprint to the surrounding areas by acquiring sugar plants at Amroha, Bijnor, Chandpur and Bulandshahar. Apart from meeting the cane potential of the said areas of cane crop Growers, Wave is also producing the Green Power and exporting it to Grid by evacuating the power at Amroha 132 KV s/s, through it’s Cogeneration Power plant facility available at Dhanaura plant. The Power is produced by burning the Sugarcane Solid Waste called Bagasse in a High Pressure Boiler of latest design with high energy efficiency and the power is produced through it’s 30 MW Steam Turbo Generator of latest technology, imported from Shin Nippon Machinery Company Ltd., Japan

Sugarcane

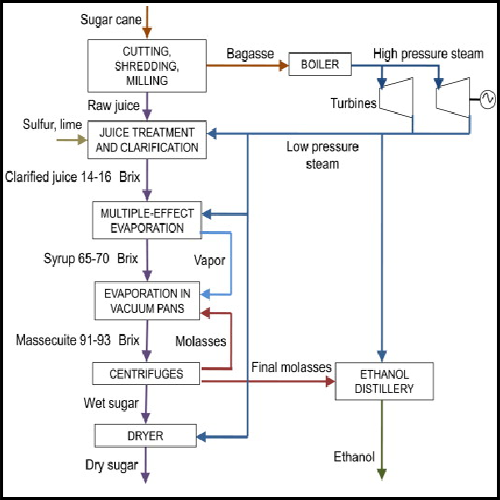

Sugar Cane is a perennial grass in the family Poaceae. It is cultivated in tropical and sub-tropical regions for the sucrose that is found in its stems. It requires a frost-free climate with sufficient rainfall during the growing season to make full use of the plant's great growth potential. The crop is harvested mechanically or by hand, chopped into lengths and conveyed rapidly to the processing plant. Here it is either milled and the juice extracted with water or the sugar is extracted by diffusion. The juice is then clarified with lime and heated to kill enzymes. The resulting thin syrup is concentrated in a series of evaporators after which further water is removed by evaporation in vacuum containers. The resulting supersaturated solution is seeded with sugar crystals and the sugar crystallizes out, is separated from the fluid and dried. Molasses a by-product of the process and the fiber from the stems, known as bagasse, is burned to provide energy for the sugar extraction process. The crystals of raw sugar have a sticky brown coating and can either be used as they are or can be bleached by sulphur di-oxide or treated in a carbonization process to produce a whiter product